Construction of a mechanical TV set

|

If you haven't read about it before you may probably wonder how this should work.

But in fact, this was the first TV system and was in use about two decades before

CRTs and electronic television would replace the mechanical system. |

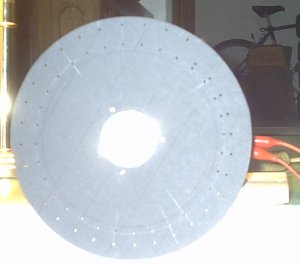

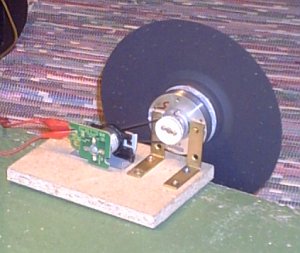

This was the first Nipkow disk I made and it is 20cm in diameter. You can see the

spiral of holes, which are by far too big. The additional inner circle of holes can

be used to measure the speed and estabishing an automatic synchronisation. This part

was not used at this point. You can see the small DC-Motor driving the disk, all parts

were salvaged from an old VCR. |  |

|

I know, it took quite some time and it is still not finished. |

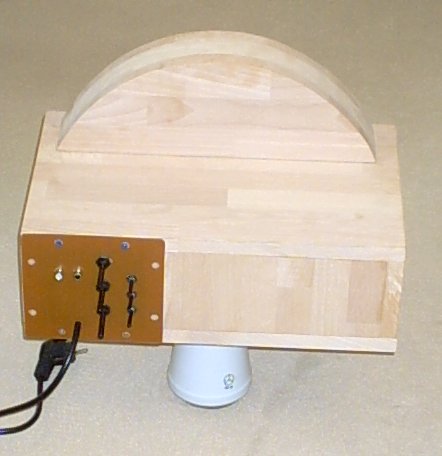

Yet some more changes. As you can guess I practically rebuilt the whole thing, at least an

entirely new cabinet from beech laminated wood which was originally inteded to end up as a

book shelf and with a thickness of 18mm is a bit on the large side.... build to resist ;-)

|  |

|

A view of the controlls located on the rear panel of the set. No knobs yet but

controlls for volume, brightness, contrast, motor speed and sync level. |

The cabinet with both extensions and sanded with fine paper, ready for varnishing or staining. |  |

|

Varnishing job half finished. Did not mess it up as bad as previously indicated, but

still a lot worse that it should be. Observed from a fair distance everythin looks

great, but a close look reveals a very unevenly applied coat of clear varnish. |

A view from the opposite site. The white aereas are remains of masking tape I haven't removed yet. |  |

|

Front view with the front panel still seperate. Behind the left hole a small speaker will be located and behind the right one you can already see the magnifying lens where the picture will apprear. |

Screenshot from the half finished device showing the NBTV logo. |  |

|

As you can see, I found time to make a front panel with two holes, one for the picture and the other for a speaker. I used a scrap piece of cloth as a speaker grill and I found, that the pattern on the cloth really gives the whole thing a somewhat qenuine appearance of anique apparatus. Although this is only the first impression and you can still clearly see its something homebuilt I am pretty satisfied with the project, now I will try to get the control circuits to run smoother and hopefully a better scanning disk. Currently you can see pictures pretty good but the image is not very stable and somewhat distorted. This is on the one hand caused by improper layout of the curcuits which are still the ones I lashed up when I started this project. On the other hand the cardboard disk is loosing shape which causes it to turn unevenly. |

|

Home |